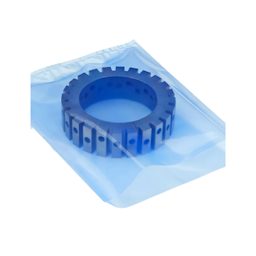

Plastic VCI Packing Poly Bag 10 X 12

₹

₹ NaN

COUNT

100 - 130

131 - 150

151 - 200

< 201

PRICE

18

17.46

17.1

16.25

Product Details

CORROSION RESISTANCE: VCI bags or Vapor Corrosion Inhibitor is developed with poly packaging films for different commercial or personal needs. The VCI molecules of the bag are protecting the metal from high corrosion levels, by forming a thin layer of the surface. It is also referred to as anti-rust plastic bags that deliver optimal results. The VCI poly bags are mainly used for the protection of metals at the time of storage or shipment.

DUST AND MOISTURE PROTECTION: The products when kept exposed become dirty with an accumulation of dust with time. Such bags are working as a dust & moisture barrier, other than a corrosion inhibitor. VCI bags are known for commercial uses where the dust amount is higher in the environment. Protect your items for a longer duration by selecting such reclosable anti-rust plastic bags. Moisture protection also results in the maintenance of the overall quality of the product.

NO WRAPPING REQUIRED: Products or items don’t need to be wrapped for storage or shipping purposes. The product can be placed directly inside the VCI bags for instant use. Unlike polythene bags or wrappers, it can be used instantly to fit personal & business requirements. The VCI plastic bags are known for simple use and great results. The wrapping of polythene on products requires time & effort. It can be used easily by placing the product inside the bag.

TRANSPARENT: The VCI packaging materials are transparent and thus allow the view of items available inside. This becomes one of the easy ways to do the identification of products from outside. The VCI poly bags maintain a high level of transparency and no need to open up every time to see the product inside. The inventory procedures are also completed easily and early with easy identification of materials present inside the bags.

USED FOR PROTECTION OF METAL PARTS: There are multiple uses for such bags across the industry and users collect such bags for personal use. Check the quality of packaging to be sure of the strength of the bags and store different items easily in them. These VCI plastic bags are typically used to keep the metal items safe from rust during all stages till the final reach out in the market. Metal parts can be kept intact for a longer period with the use of such bags.

Are you eyeing specific kinds of plastic bags that can be used safely across different installations? The VCI bags or Vapor Corrosion Inhibitors are protecting your industrial items from corrosion and dirt accumulation. It is impregnated with VCI chemicals to ensure full protection against multi-metal products. It is a transparent kind of polythene bag that doesn’t have to be wrapped around the product for suitable results. These VCI packaging materials allow easy inspection of the metal parts and allow users to maintain a kind of transparency at their work. The VCI polythene bags are used for safe packaging across the industrial space and selecting the right size becomes crucial. Do appropriate planning to buy the bags with metal and automotive parts in them. These are non-toxic & environment-friendly options to store and ship industrial products to safe locations. VCI bags are providing the opportunity to inspect the right products inside the bag. It is protecting the metal items against corrosion and thus is safely used for desirable results. The VCI active substance is fitted for different kinds of industrial parts that need careful protection and such bags are also harming the environment adversely. No worries about the damage of metal parts that would have avoided the harmful residues caused by such materials. The VCI poly bags are manufactured with organic materials and do not pose any danger to your industrial parts. Plan the buying of such bugs from appropriate stores having different items in their possession. The inhibitor bags are emitting a large number of molecules that easily settles on the surface and forms the invisible layer that fights firmly against corrosion. Plan the factory output by picking different kinds of plastic wraps or bags to fit the requirements. Check the quality of the VCI bag in the market and then take appropriate decisions on it. The VCI plastic bags are developed using different size readings and thus seals all kinds of package