5S floor marking tape standards- is it important?

A floor tape can be used for marking exceptional locations or areas so people can be aware of it. The flooring tapes help in division of places, mark danger and direction in construction work. The flooring tapes are usually bright in colour so that they are easily visible from a long distance and can make people cautious about their actions.

There are materials used for floor marking depending on the area it is used. Some floor markings are thick whereas some are comparatively thin. The main two types of 5S floor marking tape are Vinyl and PVC. The general thickness of floor marking tapes is between 50 to 60 mils thickness. The tapes are highly durable so that they can stay on the floor for a long time. If you have floor marking tape in the office your workspace is efficiently managed. So the idea of the 5S system came with the vision of making offices a better place for employees. This system has a relevance with the floor marking tapes also.

What is the 5S system and how is it relevant for floor marking tape

A 5S system was started by Hiroyuki in which he has mentioned about the main pillars of a successful visual workplace. It is somewhere applicable to the markings done in the office so that the work areas stay separated and different. The idea was brilliantly executed with the help of the 5S system where each has an impact on the floor marking methods and they are as follows,

Sort

This is the first step where you can select the areas where you need to add floor tapes. This can be hazardous zones of the business or the locations where you want to keep heavy machinery and where the other substances of manufacturing.

Set in order

In a business all the assets and tools should be set in order so that they can be used whenever needed without facing the issue of finding it. The set in order step helps you to divide the items as per their urgency in a systematic manner. Each colour tape is placed based on the urgency of the item when it is set in order.

Shine

The shining step aims to focus on the growth and productivity of the business with the help of flooring tapes. When sorting different areas it is important to mark the areas separately where conditions of the items are not good. This helps the workers differentiate the area and work on those zones which require shine that is repair and cleanliness.

Standardise

Once poor condition zones are recognised and cleaned properly the next important step is to maintain that condition for a long period of time. This means that after sorting areas, keeping the areas free from dirt and mess is needed so that you can put standard colour tape to make people aware of it.

Sustain

Division of different zones of the workplace and working on their development is not enough for a healthy work environment. Once all the steps are followed correctly the maintenance of the efforts is also required. There should be a good practice of following the above four steps in every work done and in asset management with the help of floor tapes so that organisation can run smoothly.

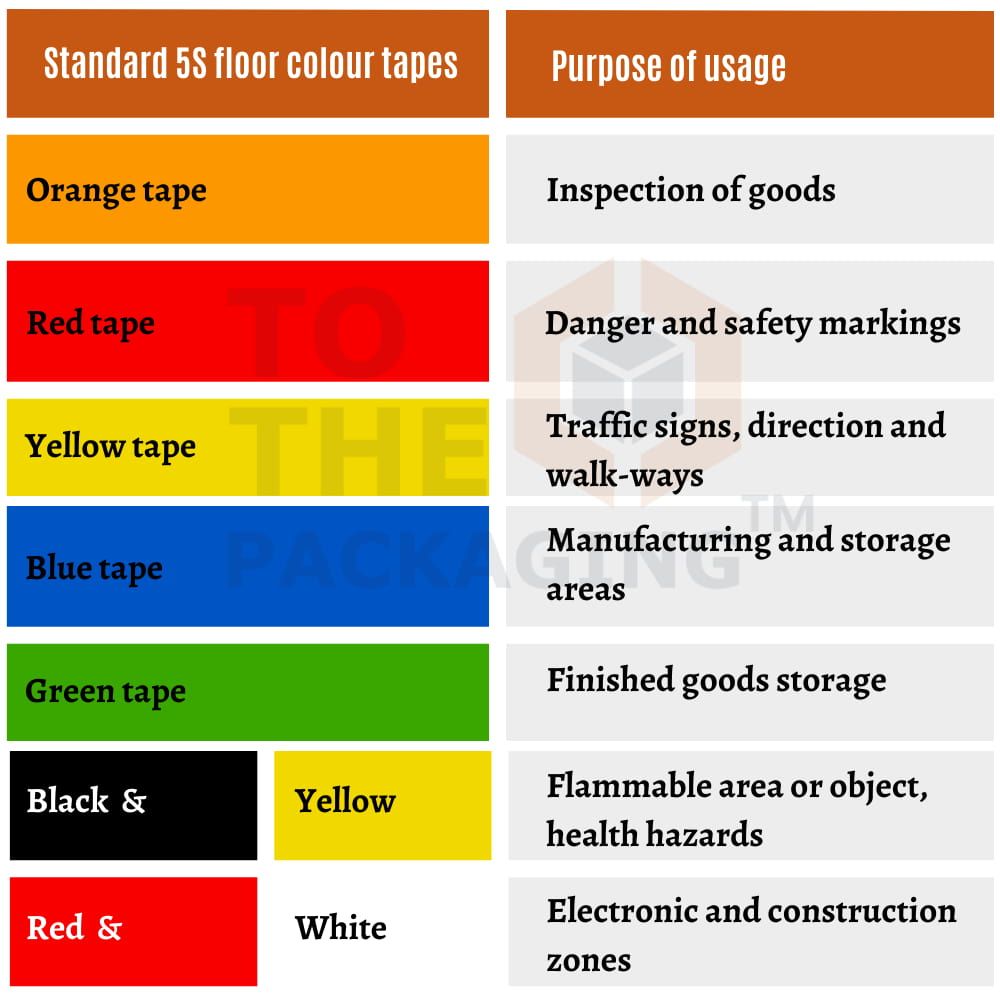

Significance of each colours standards in 5S floor marking tape

Each of the colour standards of the 5S floor marking tape has a different purpose which is why it is used. Usually all the floor marking colours are bright in nature so that they are easily visible. The most common floor marking tapes are,

Orange tape: Inspection of the materials are going on to check its quality for future production. The tape is also used for traffic guidance in general life.

Red tape: Red colour stands for the sign of danger detection so the tape is marked for safety and first aid. The accidental areas can also be marked with the help of red tapes.

Yellow tape: The yellow tapes are quite useful for safety on the traffic lanes and footpaths. The safety of machines can also be marked with this tape.

Blue tape: The areas where inventory is kept can be marked with blue tapes. Even the raw material storage areas can be handled with blue tapes. Even the areas where the raw materials are inspected use blue tapes for marking.

Green tape: When the production of the items are done properly the finished goods are stored together. For that reason the green tape can be used to mark the storage area.

Black and yellow: On the factories and restaurants these are often used as they define risky containers and flammable goods. This makes people aware of not going to the zone which can catch fire very easily. High caution zones and chemical factories also use this tape

Red and white: These tapes are generally used for safety for electrical hazards like shock driven zones and construction lightning zones. The polls which should not be touched near the backside of hotels and automobile factories are wrapped with red and white tapes for safety.

What are uses of 5S flooring tape- how do you apply them?

When you see a floor marking tape do you wonder why it is used and what impact it gives to the people who see it? The answer is very simple: flooring tapes try to indicate something based on their colours. The main uses of a flooring tapes include,

For facilities

The floor tapes play a huge role in differentiating facilities and requirements of general people. When a marking tape is used people can take the public services easily without any guidance. In hospitals and factories the floor tapes help in dividing areas for staff and ordinary people. Sometimes the tapes are used for directions in hotels and public transports.

For awareness

Creating awareness among the people is important in the surroundings. With the help of coloured tapes people can be aware of their environment. For instance when a construction is going on, labour marks the site so that people know about the work in progress or unsafe zones. This makes the people more knowledgeable about their areas and locations

For safety

The safety markings are equally important along with awareness marking. There are factories who work with hazardous substances and keep chemical liquids in containers as well. So if the labourers unknowingly enter the accident prone zones they can see the tapes wrapped on vessels or on the floors for safety.

For directions

Reaching a new location is hard so with a flooring tape the areas can be marked by doing arrow marking on the floors. People can easily follow the directions marked and reach the location on time. These markings are usually found in airports, stations and bus hubs.

For division

Division of spaces are required when a construction work is going on or measurement of floor is done for designing a house. So if the colour standard tapes are used the spaces can be divided easily and differences can be marked also.

For dance floor

A very uncommon use of the colour tapes are on dance floors. It is often found that colour tapes are attached on a stage to make it look bright and beautiful. When the button lights of the stage are switched on the colour tapes marked on the dance floor looks extremely attractive and appealing.

Industry usage of 5s floor marking tapes

The floor marking tapes are used by different sectors and industries. The usage of the tapes are different everywhere. Each industry tries to make the floor tape useful as per their services. So the industrial usage of flooring tapes has increased for awareness and safety. The main sectors of the economy using floor tapes are the followings,

- Health industry

- Factories

- Construction

- Security teams

- Human welfare

The operations of these industries and sectors become more effective when the work is divided with the 5S system with the use of the flooring tapes. As the 5 techniques of the workplace says that each technique should help in making the work easy and manageable. So when the flooring tapes are attached on the floors the zones of work are neatly divided and the need of the work is also recognized.

To The Packaging, is a firm with more than 20 years of experience in the packaging business. We believe in creating innovative solutions for all kinds of packaging problems for big and small businesses.