How To Calculate GSM Of Carton Box and its Importance?

In our daily life, we see and observe many things. There are many things that have a huge impact on our life but we don’t pay much attention to them till we need it. One of those things is carton boxes. Call it corrugated boxes, carton boxes, packaging boxes, or whatever you want.

Carton boxes have become an integral part of our life and our business. These days we can find all the things that we need online. This has created a demand for packaging and shipping of the packaging.

If you are a business owner, then you should know the importance of corrugated boxes as well as there are many things that you should know before you buy the boxes for your business. One of those things is GSM.

In this article, we will talk about what GSM is, its importance, how to calculate it as well as other things to keep in mind while looking for the right kind of boxes.

What is GSM?

GSM is short for gram per square meter. GSM stands for the weight of paper per m2 in gram. The paper which is higher in GSM is perceived as higher quality one as compared to the paper which is lower in the GSM scale.

We can understand this by an example like a tissue paper has lower GSM as it is thin and its weight per square meter would be lower when we compare it to a poster. The weight of the poster per square meter would be higher than that of the tissue paper.

We can see the difference in their strength, thickness as well as the other properties.

What is the importance of GSM?

In the above section, we have talked about what GSM is. Now, we will talk about why we need GSM.

GSM is an important feature that helps us to definite the quality of different materials. As we have read before GSM is the weight of material per metre square. This single factor will help us to categorize things according to their quality and strength. With the help of GSM, we can calculate other factors too.

GSM is used in paper, textiles and cardboard. As this article is about the GSM of a corrugated box, we will talk about it only. GSM of the corrugated box is used to determine many things like hardness, thickness, durability, moisture content, abrasive nature etc.

With the help of GSM, we can find the bursting strength, box compressions, Edge crush test, puncture resistance and many more things.

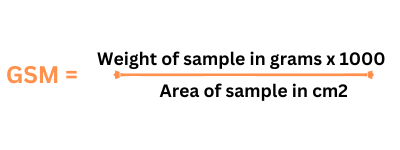

What is the formula for calculating a corrugated box?

We have talked about how important the GSM factor is and now we will tell you how can you calculate it.

It is important to note that the weight of the paper sample should be in grams as well as the area must be in cm2

You can find the area of a piece of paper by cutting it into a square after measuring the sides. Suppose you get x as the length of the side. You can now easily use this formula to get the area of the square piece.

Area of square = side x side

Using all these formulas would help you to get the GSM of the sample corrugated box.

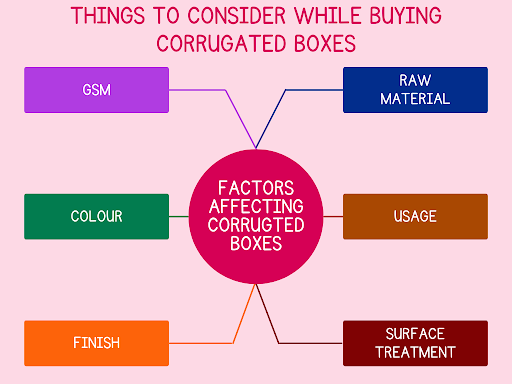

What is the other factor to consider while choosing packaging boxes?

We have talked about how important the GSM factor is for corrugated boxes. In this section, we will talk about some other things that you should consider while choosing your preferred packaging boxes. There are more than 10,000 different categories and even more types of paperboard. So it is kind of impossible to write down all the types of categories.

So we will try to categorise them based on major things that are looked at and asked by the people.

1. Based on Basis weight

Basis weight is a term which is used by the paper manufacturer when 500 pages are stacked one upon another to cut them into a specific size.

The size of the paper is categorised by the different dimensions of the different types of papers. We can name some like Bond, Cover, Newspaper, Digital, Offset, Index, label, tag or bristol.

We can divide different types of paper according to their basis weight in the following ways:

- Tissue: As the name says, tissues are lightweight paper types. Their weight would be less than 40g/m2.

- Paper: The weight of the paper would be in a range as there are different types of paper that are made for several purposes. The range would lie from 40-120g/m2 .

- Paperboard: As the name suggests this category will be for the sheet which would resemble the thickness of the packaging of the cosmetic, food, dog food etc. The range would lie from 120-200g/m2 .

- Board: This type of sheet can be seen to be used as seeing high-quality greeting cards. These range above the 200g/m2 .

When it comes to choosing a carton we should not only look for weight but also the number of layers used to make it. There are three types of corrugated boxes, if you would like to know about them. You can read this blog about the difference between double, triple and single-ply corrugated boxes

2. Based on colour

Another way to categorise would be by colour. We all must have seen different types of colour paper which are different shades. All those things depend on the fact if the paper is bleached or not, or if there is use of any pigment.

- Bleached - Almost all the white or off-white paper is bleached. The shade of the witness depends on the strength of the bleach. The higher the concentration of the bleach, the whiter the paper is.

- Unbleached - The brown paper that you find on the covers or the kraft paper that you find in the packaging are good examples of unbleached paper. This is also used to make kraft paper tape which is a sustainable alternative to traditional tape.

- Dye or pigment - You might have seen paper of different colours. Many of us must have used them in our school projects. Well, the papers have been dyed in different shades to give them a striking bold finish.

4. Based on surface treatment

Surface treatment can be understood as the coating that is done on the sheet of paper to improve its texture and printability. We can divide it into three parts which are written down below.

- Coated with clay or other things

- Uncoated paper

- Laminated paper with metals like aluminium

5. Based on the raw material

We know how different raw materials impact the properties of the finished product. It is true with paper as well, for example, if the paper is made from virgin wood pulp would be different from the recycled pulp.

We can divide them into three parts:

- Wood pulp

- Recycled material

- Agricultural residue

6. Based on usage

We can divide the paper on the basis of their usage. As different users have different requirements. Paperboard which is used for food packaging will not be used for paper used to make packaging for electrical wires and vice versa. We can categorize them according to the industries.

- Food industry like tea bags, candy wrappings etc.

- Industrial like packaging, wrapping, electrical etc

- Cultural like offices, schools,

Conclusion

We have reached the end of this article which is about how to calculate the GSM of the carton box. Along with this, we have also talked about what GSM is as well as its importance. In the end, we talked about the other factors we should consider about choosing packaging boxes.

Thank you for reading till the end.

Suman Mandal has been in the packaging industry for a long time. She is passionate about the innovative ways this industry comes up with. Currently, she is writing for To The Packaging about various packaging solutions.